Vending machines have evolved into connected retail endpoints. The machine is only the front end. Performance depends on four things that stay true across locations: how people pay, what you stock, how reliably the machine runs, and how efficiently you service it.

The facts below focus on how vending works today, not trivia.

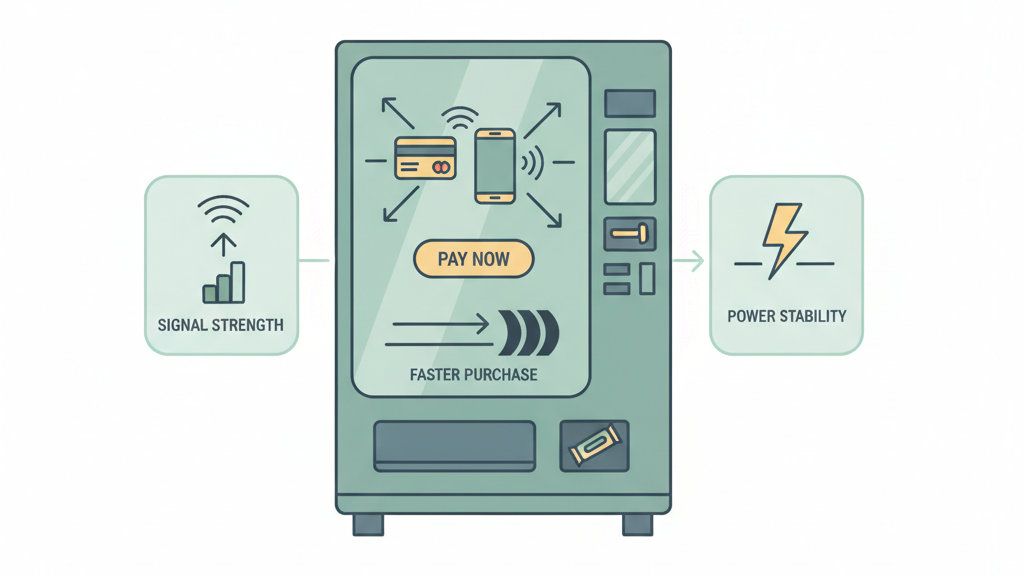

Card, mobile pay, and tap-to-pay reduce friction and increase conversion. Cash still exists, but cashless makes buying faster and reduces walk-aways caused by missing change.

Connectivity, power quality, and placement conditions can drive payment errors. Solving signal strength and power stability often fixes “payment device problems” that upgrades cannot.

Vending is still retail. Visibility and selection order affect conversion. Eye-level placement for best sellers and clear product presentation usually lift sales without changing the location.

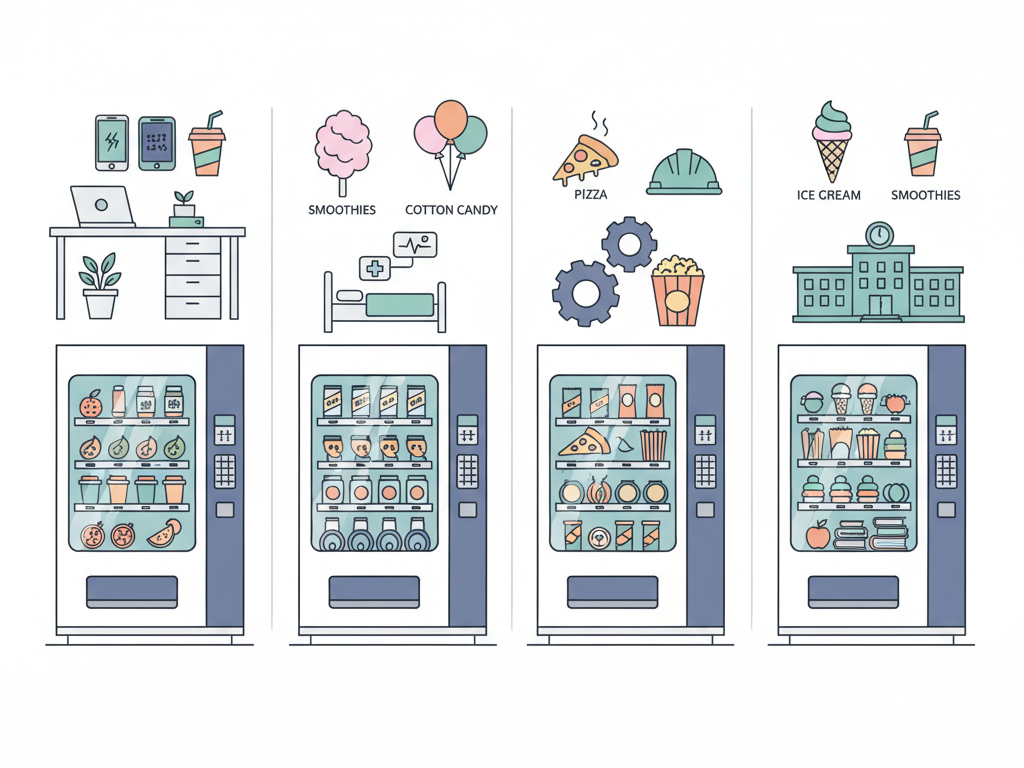

A strong location cannot rescue a weak assortment. Sites convert best when products match the people on-site, their schedule, and their purchase intent.

Hospitals, factories, offices, and schools behave like different markets. Peak times, preferred price points, and product categories change by environment.

Many sites use vending for personal care, PPE, electronics, and facility essentials. The best-performing machines often sell what the site needs immediately, not what is trendy.

Telemetry turns vending into a measurable system. Operators can track sales patterns, stock levels, and fault alerts instead of guessing.

Overstock increases spoilage and tied-up cash. Understock creates empty spirals and missed revenue. Strong operators tune par levels using data, not habit.

With machine data, routes can match real needs. Fewer emergency trips, fewer stockouts, and lower labor cost usually matter as much as top-line sales.

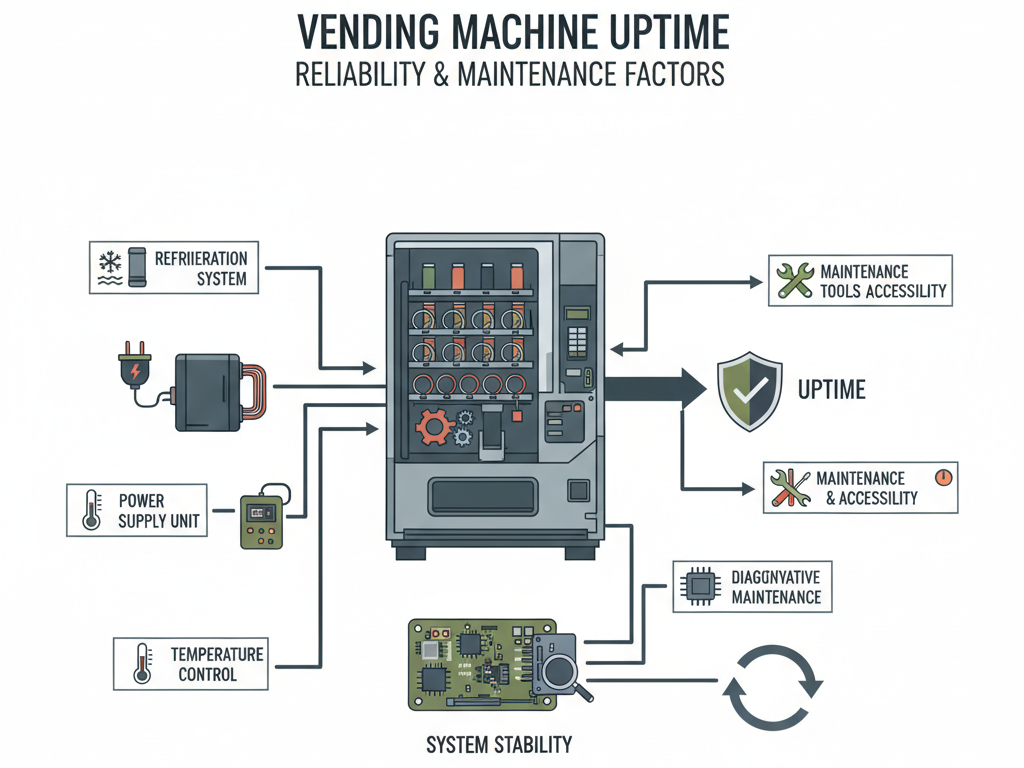

A machine that fails often loses money even with good traffic. Downtime means lost revenue and weaker repeat purchase behavior.

Large screens and advanced interfaces can help, but most operations win with machines that dispense consistently, accept payments reliably, and are easy to service.

Maintenance discipline reduces failures, protects conversion, and lowers service costs. It is often the fastest path to stable performance.

Refrigeration dominates power draw for cold machines. Efficiency features affect lifetime cost and can help stabilize product quality.

Poor temperature control leads to quality complaints for sensitive items. Stable temperature reduces refunds and protects margin.

Door width, elevator limits, power availability, and service clearance often determine what you can place. A machine that is hard to refill or service will lose money over time.

Cash collection adds time and exposure to theft and counting errors. Even when cash remains meaningful, reducing cash complexity improves operational control.

Two busy sites can perform very differently if one location invites tampering. Site selection should consider basic security conditions, not just foot traffic.

Food safety rules, electrical compliance, and age-restricted controls can affect what you stock and how you operate. Product strategy should account for compliance early.

Vending succeeds when you treat it like a system, not a box in a hallway. Cashless—including NFC payments—reduces friction. Product mix matches the site. Telemetry turns guesses into decisions. Maintenance protects uptime. Restocking and routing protect margin.

The most reliable vending programs are the ones that keep machines stocked, working, and easy to buy from—day after day.

Notification